Cover Plates

The plates are movably mounted on the cultivators section with a rocker, thanks to which they move independently of the section by “sliding” on the soil surface. They are used to protect the crop from backfilling. Thanks to the use of cover plates, the plants are not covered with soil coming out from under the machine’s cultivation tools. They cover the plants along the entire working length of the weeding section. The sheets glide on the ground and gently push back the leaves. The cover plates can be adjusted by setting the necessary distance from seedlings.

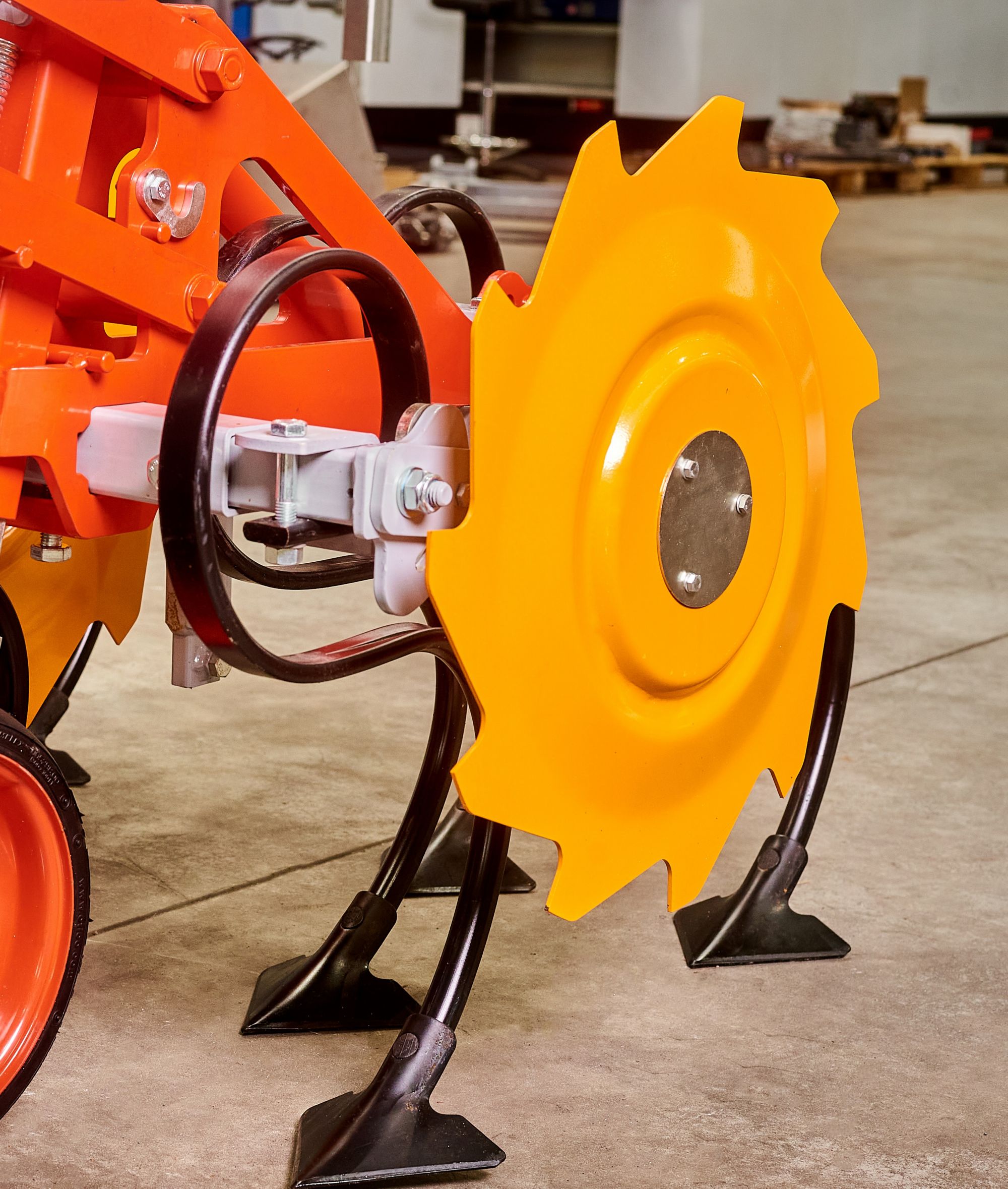

Cover Shields

Cover shields are mounted at the front of the section and are adjustable. They cover the seedlings from the soil coming out from under the spring tines of the cultivator. Due to their operation, the disc rolls over overgrown, protruding elements of the crop, avoiding the possibility of damaging or uprooting the plant. Mounting on the swing arm ensures continuous contact with the ground and optimum performance.

Goosefoot 105 or 150mm

With the help of the goosefoot, the spring tines are able to penetrate the soil deeper, removing weeds with roots. In addition, their width at the ends of the teeth increases the working area of the weeding section

French wheels

It is a pneumatic wheel, thanks to which the clay soil does not stick too much. In addition, the wheel has an increased diameter of 300mmx100mm to prevent the collapse of the cultivator section on sandy soils.

Finger Weeder Kress to main frame

The purpose of using finger weeder stars is to remove weeds between plants. Stars is a system of mechanical weed control in rows. They allow you to limit or even exclude manual weeding in rows. Star elements made of special plastic penetrate the ground at a depth of 2-4 cm, directly at the plant, remove young seedlings of weeds. To keep the crop free of unwanted plants, use the stars every 7-10 days during periods of heavy weed growth. Frequent use of the weeder equipped with finger weeder gives the effect of reducing human labor by 90%. Please note that plastic elements are only able to remove young seedlings up to 5 cm tall. Older weeds have a deeper root system that is already beyond the reach of the weeding stars. Therefore, weeds cannot be allowed to overgrow. The stars are made of plastic with a diameter of 370mm and different hardnesses selected according to the type of soil and crop specifications. The Kress system is mounted on rockers and has a star angle adjustment.

String Roller

Connected to the tractor cultivator, they fulfill many functions. They are used for tedding the soil, compact the soil, which prevents the soil from releasing moisture, break lumps with weeds, shaking them to the surface of the soil, where they are unable to regrow and dry up. After passing such a shaft, a thin, well-crushed, kneaded and slightly loosened layer is formed. The width of the rollers is regulated depending on the width of the inter-rows. We have two versions of rollers that differ in width adjustment: 200mm-400mm, 300-600mm

Cutting disc

They are mounted to the cultivator section. Set at the appropriate depth in the ground, they are used to trim unnecessary shoots (e.g. strawberry shoots). In addition, they act as shields and protect the seedlings from being buried.

Angular Blades

These knives are used to cut off angular regrowth or weeds firmly rooted in the ground.

Ridging Coulter

Used for cultivation in ridges, e.g. potatoes and other root crops. The coulter can be used for weeding, soil loosening between the rows, and separating the rows of plants. It is mounted in the middle of the section

Ridging Plates

Mounted to the machine section. They are used for precise covering of rows of crops with a soil. The platter has an adjustment of the turning angle and the angle of inclination as well as the extension. Appropriate setting ensures optimal ridging, according to the intended planting.

Hydraulically Steered Frame

If the machine is heavy and equipped with a large number of sections, and if the field on which it works is sloping, then the person driving in the case of manual steering is heavily loaded. That’s why we offer hydraulic instead of manual control for our cultivators. This can be hydraulic control from the cultivator’s seat or control from the tractor cockpit using the joystick.

Hydraulically Folded Frame

If the span of the machine prevents free transport on public roads, we offer a cultivator with a hydraulically folded beam. It is possible to order a cultivator simultaneously with a hydraulic steering system and a folding beam.