Offer

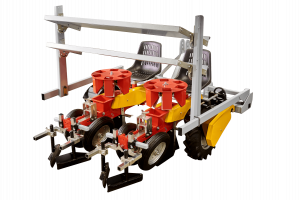

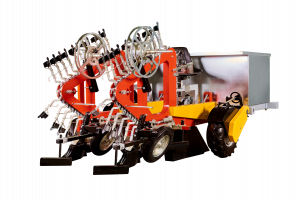

Model SSZ

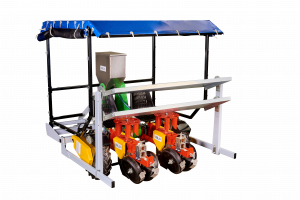

In the standard version, the machine is equipped with a container for seedlings located at the back of the machine. In the container there is a person who prepares the seedlings while the machine is driving and puts them on the table right behind the people operating the planting sections, which greatly speeds up and improves the entire planting process. It is possible, instead of containers for seedlings, to create a platform for the entire width of the machine on which a person moves. By drawing seedlings from the trays located on the edge of the sides of the planter, it supports the planting staff.

Machine Parameters

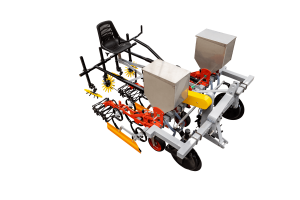

- Semi-automatic planting of rootstocks and small trees

- The model is characterized by high work ergonomics

- The planter guarantees very precise placement of seedlings without tucking the root system

- As standard, it is equipped with a distributor consisting of 12 fingers for a planting density of 25 cm. It allows planting with a maximum density of 10 cm (optional) and a minimum row spacing of 80 cm

- Maximum length of plants – 110 cm (including the root system)

- Planting density is adjusted by changing the number of fingers (10, 15, 20, 25, 30, 40, 50, 60, 75, 80cm)

- The efficiency of each section is 2000-2500 seedlings/hour

Application

Model SSZ

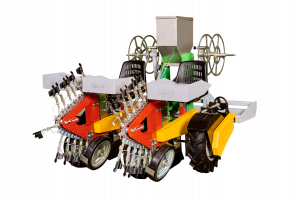

Nursery planter Model SSZ is designed for row planting of nursery material. The machine is used for planting rootstocks of cherries, apple trees, raspberries, aronia, currants, grapes, etc. The planter guarantees an even planting depth, precise vertical positioning of the seedlings and a constant distance between plants in a row, optimal covering of plants and proper pressing of seedlings, which has a positive effect on their development. The planter consists of self-contained sections mounted pivotally on a crossbeam using position-adjustable clamps. A container or smaller containers per section is placed on the beam. Depending on the needs, the planter can be a unit consisting of 1 to 4 sections.

The planter consists of self-contained sections mounted pivotally on a crossbeam using position-adjustable clamps. A container or smaller containers per section is placed on the beam.

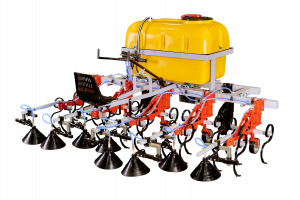

*On request, it is possible to place a root fertilizer dispenser on the planter and a system for developing a drip line, laid on the ground or sunk under the soil surface.

It is not possible to buy this option for an existing planter that was not intended for expansion during production.

* It is possible to produce and install additional, non-standard storages for seedlings, according to the customer’s drawing

Any questions?

Call to us!

(+48 ) 81 751 07 85